Wastewater treatment systems using bio-films that grow attached to a support media are an alternative to the widely used suspended growth activated sludge process. Different fixed growth biofilm reactors are commercially used for the treatment of municipal as well as industrial wastewater. FBBRs are based on aerated submerged fixed open structured plastic media for the support of the biofilm. They are generally operated without sludge recirculation in order to avoid clogging of the support media and problems with the control of the biofilm. Reactor and process design considerations for these reactors are reviewed. Measures to ensure the development and maintenance of an active biofilm are examined. FBBRs have been applied successfully to small wastewater treatment plants where complete nitrification but no high degree of denitrification is necessary. For the pre-treatment of industrial wastewater the use of SFBBRs is advantageous, especially in cases of wastewater with high organic loading or high content of compounds with low biodegradability. Performance data from exemplary commercial plants are given. Ongoing research and development efforts aim at achieving a high simultaneous total nitrogen (TN) removal of aerated SFBBRs and at improving the efficiency of TN removal in anoxic FBBRs.

BENEFITS

- No odor.

- Low running costs.

- High performance with high quality.

- Easy installation and handling.

- Sludge stabilisation/Sludge treatment.

- Stable and very robust process technology.

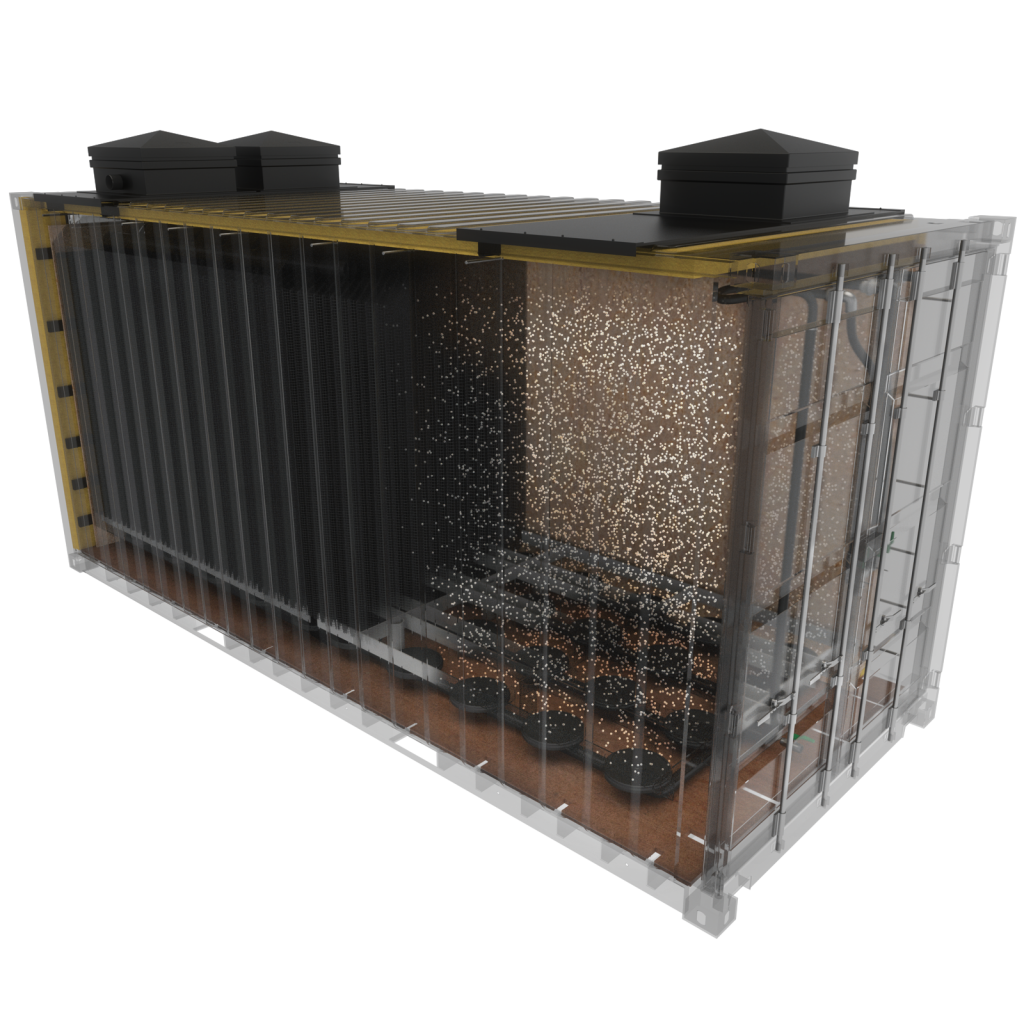

WATEQ fixed bed plants are durable, easy-to-handle solutions for complex cases of application. Up to now, in situations where the wastewater production was fluctuating over time or in terms of content, it has been required to continuously measure the control parameters such as sludge content (via the dried matter measurement) in order to optimise operation. The sewage treatment plant, however, should be regulated automatically over a wide range and be adjustable with simple variables. This is only possible in a biology with fixed sedentary medium (fixed bed), since the consistency and volume of the submersed sludge is of minor importance.

Application Size:

There is no limit or restriction on the size of the project that our containerised systems can be utilized for, as the system is modular. Waste water treatment systems from 50 to 20.000 persons, or 8-800m3 of wastewater per day have been commissioned. For larger applications it may become more financially viable to make use of SBR equipment solutions in tanks and structures that are constructed onsite. Any effluent quality can be achieved.

Advantages of WATEQ FBBR packaged wastewater treatment:

- Market leading, state of the art technology is built into our container solutions, which are manufactured in a quality controlled environment and are factory tested.

- The complete system with all its components is provided from one supplier, thus limiting financial risk.

- The waste water container treatment plants are suitably designed for all climate zones and achieve maximum efficiency in each process step.

- The system can easily be transported by land or sea and is easily setup in isolated remote and off the grid areas.

- Low costs for scheduling and construction, as no infrastructure or buildings are required. Only a solid base or foundation is needed on which to place the containers.

- The solution is modular, fully automatic plug & play and can be tailored to the specific local conditions and project requirements.

- Rapid installation and setup of the system as it is delivered with all equipment preinstalled. Simply connect the system to the electricity supply, then connect the inlets and outlets.

- It can be rapidly dismantled to be quickly and easily relocated to a new location.

- Low energy costs due to the integrated energy saving mode.

- Imperceptible noise as the entire container treatment plant is enclosed.

- Standard, locally obtainable spare parts can be used for maintenance, thus saving time and money.

- Can be used as a fixed or temporary solution for any existing treatment plant, in a supporting function, during improvements being undertaken [new, upgrade, bypass.

- The modules can be added on to upgrade existing WWTPs to meet new emission limits.

- It is flexible, as systems can be designed as complete waste water treatment plants or hybrid systems, depending on the requirements.

- Designed for waste water treatment, sludge treatment and industrial water treatment for different medium and large scale applications such as the food industry or for remote communities without access to a municipal sewage system.