WATEQ MBBR plants are the core process unit of a complete Package Sewage Treatment Plant which would incorporate a combined pretreatment system, followed by further polishing stages such as filtration and disinfection (UV or chlorination).

The MBBR units can also be used for extensive and high-rate bio-degradation in a wide range of Industrial Wastewater. They can be combined effectively with other treatment methods such as Physical-Chemical or Anaerobic, to provide Total Solutions for a vast range of Wastewater Treatment facilities.

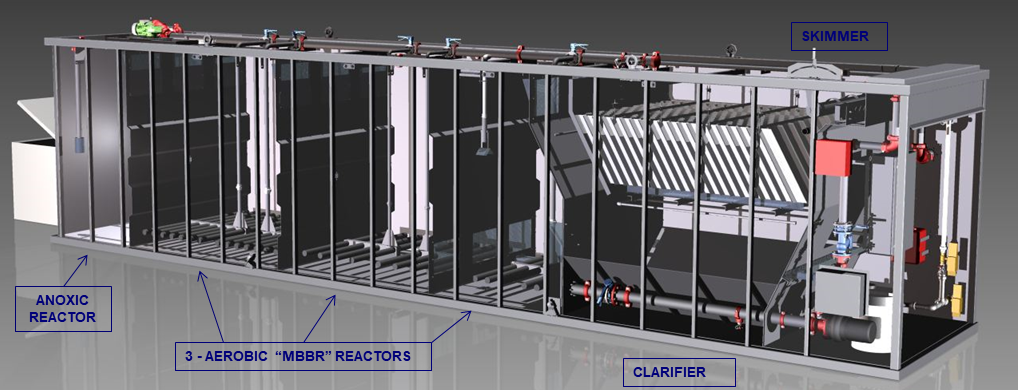

WATEQ MBBR Plants is an effective biological treatment unit based on the Moving Bed Biofilm Reactor Technology with Integrated Fixed Film Activated Sludge and TUBE-Settling technologies. It is unique due to its compactness and performance concerning volumetric efficiency. These technologies are combined in a prefabricated, standardized tank system with variable length, suitable for overseas transportation. The overall size of the plant is based on the ISO freight container dimensions.

MBBR Industries:

- Dairy processing (milk, cheese, yogurt)

- Beverage factories (breweries, juice, soda)

- Automotive Industry

- Metal plating and finishing

- Municipal sewage plants

- Chemical industries

- Pulp & paper

- Food & beverage

- Coke & steel plants

- Aquaculture & Koi ponds

WATEQ MBBR Plants Effluent Quality:

BOD5 < 20-30 mg/L

TSS < 20-30 mg/L

TN < 30 mg/L

TP < 9* mg/L

The above values are for the following wastewater quality: Temperature 15-20°C, BOD5: 300 mg/L, COD: 600 mg/L, TSS: 350 mg/L, TN: 45 mg/L, TP: 12mg/L.

** Concentrations of TP ≤ 3 mg/L can be achieved by direct dose of flocculant in the Bioreactor.

Advantages:

Smart Design

• Pre-engineered & prefabricated plants

• Modular design

• Compact and high-rate performance

• Fully tested before dispatch

• Ready to plug & play

• Space saving – Small footprint

Easy & Reliable Operation

• Fully automatic – PLC-controlled system

• User-friendly interface (touch screen HMI)

• Remote monitoring

• Low maintenance requirements

• Self-cleaning mechanisms incorporated

WATEQ offers several standard models ranging from 60 to 700 m3/day and all models have integrated machine rooms with PLC-equipped electrical panels and remote monitoring options.